Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

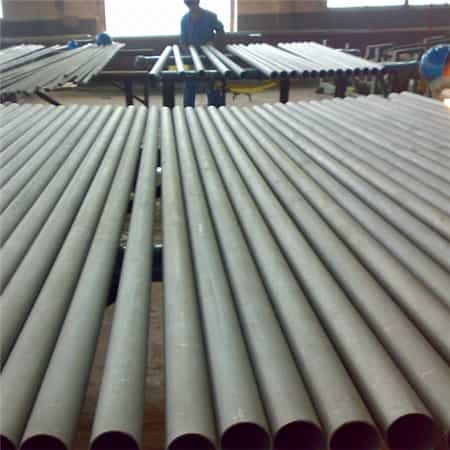

TP321 TP321H 1.4541 1.4878 Stainless Steel Pipe and Tube

Stainless 321 (UNS S32100) is a titanium stabilized austenitic stainless steel with good general corrosion resistance. It has excellent resistance to intergranular corrosion after exposure to temperatures in the chromium carbide precipitation range of 800 – 1500°F (427 – 816°C). The alloy resists oxidation to 1500°F (816°C) and has higher creep and stress rupture properties than alloys 304 and 304L. It also possesses good low temperature toughness.

Alloy 321H (UNS S32109) stainless steel plate is the higher carbon (0.04 – 0.10) version of the alloy. It was developed for enhanced creep resistance and for higher strength at temperatures above 1000F (537 C). In most instances, the carbon content of the plate enables dual certification.

Stainless Seamless Fluid Pipe Quality Control

- Raw materials pipe blank quality classification: high quality, medium, economical

- Raw materials inspection after receive in factory

- After pickled, tube will be grinded careful to less defect

- Multiple cold drawn/rolled process for precision dimension

- Standard heat-treated of continuous annealed/solution for better property, intergranular corrosion

- Full Inspection: ET, UT, Hydraulic Test, Penetration Test, Grinded, Sand Blast, Print Making

*Besides bleow, we can supply comfortable price with equivalents quality for you! Welcome contact us.

We also can supply other kinds of:

- Seamless Stainless Steel Pipe & Tube

- Welded Stainless Steel Pipe & Tube

- U Type Stainless Steel Pipe & Tube

- Coil Type Stainless Steel Pipe & Tube(Max 300meter), seamless or welded

- Annealed Pickled AP Stainless Steel Pipe & Tube (Ra ≤5μm)

- Bright Annealed BA Stainless Steel Pipe & Tube (Ra ≤8μm)

- Mechanical Polished MP Stainless Steel Pipe & Tube (Ra ≤8μm)

- Electro Polished EP Stainless Steel Pipe & Tube (Ra ≤25μm)

- Sanitary Stainless Steel Pipe & Tube

- Capilllary Stainless Steel Pipe & Tube

- Instrument Stainless Steel Pipe & Tube

Grade Specification Comparison

| Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

| BS | En | No | Name | ||||

| 321 | S32100 | 321S31 | 58B, 58C | 1.4541 | X6CrNiTi18-10 | 2337 | SUS 321 |

| 321H | S32109 | 321S12 | 321S51 | 1.4878 | X8CrNiTi18-10 | 2337 | SUS321H |

Chemical Properties

| Grade | Cr | Ni | C | Si | Mn | P | S | N | Ti | Fe |

| 321 | min:17.0

max:19.0 |

min: 9.0

max:12.0 |

max:0.08 | max:0.75 | max:2.0 | max:0.045 | max:0.03 | max:0.10 | min:5*(C+N)

max:0.70 |

Balance |

| 321H | min:17.0

max:19.0 |

min: 9.0

max:12.0 |

min:0.04

max:0.10 |

min:18.0

max:20.0 |

max:2.0 | max:0.045 | max:0.03 | max:0.10 | min:5*(C+N)

max:0.70 |

Balance |

Mechanical Properties

| Grade | Tensile Strength (MPa) min | Yield Strength 0.2% Proof (MPa) min | Elongation (% in 50 mm) min | Hardness | |

| Rockwell B (HR B) max | Brinell (HB) max | ||||

| 321 | 515 | 205 | 40 | 95 | 217 |

| 321H | 515 | 205 | 40 | 95 | 217 |

Stainless Steel Tube & Pipe Sizes:

Outsider Diameter OD : 6-630mm ; WT 3-60mm ; L max 16meter

Stainless Steel Tube Delivery Condition:

- Solution Treatment

Stainless Tube Surface:

Acid pickling – pre-passivation process of treating stainless steel parts with an acid solution, typically hydrochloric or sulfuric acid, which can remove oxide scale and heat tint while dissolving steel flecks embedded in the part.

Polishing – P grade sandpaper: P150, P200, P250, P300, P400, P500, P600, P700, P800

Stainless Pipe Inspection and Testing:

Chamical analysis / Tensile test at room temperature / flattening test / ring tensile test / drift expemdomg test / ring expanding test / leak tightness test / Tensile test at elevated temperature / impact test at room temperature / impact test at low temperature / eddy current test / ultrasonic test / magnetic flux leakage test

Stainless Tube Marking and Packages:

In addition to the marking prescribed in specification as client’s request.

Bare / Nylon / Plastic / Wooden Case

Corrosion Resistance

Equivalent to Grade 304 in the annealed condition, and superior if a weldment in these grades has not been post-weld annealed or if the application involves service in the 425-900 °C range. Subject to pitting and crevice corrosion in warm chloride environments, and to stress corrosion cracking above about 60 °C. Considered resistant to potable water with up to about 200 mg/L chlorides at ambient temperatures, reducing to about 150 mg/L at 60 °C.

Heat Resistance

Good oxidation resistance in intermittent service to 900 °C and in continuous service to 925 °C. These grades perform well in the 425-900 °C range, and particularly where subsequent aqueous corrosive conditions are present. 321H has higher hot strength, and is particularly suitable for high temperature structural applications.

Heat Treatment

Solution Treatment (Annealing) – heat to 950-1120 °C and cool rapidly for maximum corrosion resistance.

Stabilising – heat to 870-900 °C for 1 hour per 25mm of thickness and air cool. Stabilisation is recommended for most severe service conditions (above 425 °C) and particularly for material annealed at the upper side of the annealing temperature range.

Stress Relief – Heat to 700 °C for 1 to 2 hours and air cool.

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.

Can’t Find What You Looking for? Check Popular Items Blew.

Direct from the Source and Deliver to You in a Very Fast and Efficient Timeframe.