Project Description

Commitment to You

We are committed to integrate steel resources in china and serve the global steel market. We have 15+ years of experience in steel researching, production, managing and sales.

Our ability to purchase materials directly from leading mills will give you the competitive edge. Any Questions Just Call +86-731-89903933

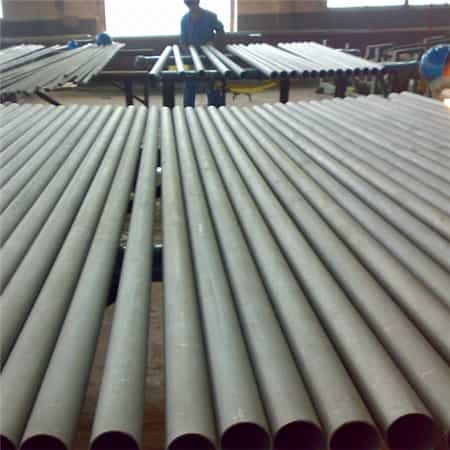

2304 S32304 1.4362 Duplex Stainless Steel Pipe and Tube

Duplex Alloy 2304 is a two-phase, ferritic, austenitic 23% chromium, 4% nickel, molybdenum-free duplex stainless steel. It has similar corrosion resistance properties to 316L. Furthemore, its mechanical properties are twice those of 304L/316L austenitic grades. This allows the designer to save weight, particularly for properly designed pressure vessel applications. The alloy is partcularly suitable for applications covering the -50 °C/+300 °C temperature range.

Stainless Seamless Fluid Pipe Quality Control

- Raw materials pipe blank quality classification: high quality, medium, economical

- Raw materials inspection after receive in factory

- After pickled, tube will be grinded careful to less defect

- Multiple cold drawn/rolled process for precision dimension

- Standard heat-treated of continuous annealed/solution for better property, intergranular corrosion

- Full Inspection: ET, UT, Hydraulic Test, Penetration Test, Grinded, Sand Blast, Print Making

*Besides bleow, we can supply comfortable price with equivalents quality for you! Welcome contact us.

We also can supply other kinds of:

- Seamless Stainless Steel Pipe & Tube

- Welded Stainless Steel Pipe & Tube

- U Type Stainless Steel Pipe & Tube

- Coil Type Stainless Steel Pipe & Tube(Max 300meter), seamless or welded

- Annealed Pickled AP Stainless Steel Pipe & Tube (Ra ≤5μm)

- Bright Annealed BA Stainless Steel Pipe & Tube (Ra ≤8μm)

- Mechanical Polished MP Stainless Steel Pipe & Tube (Ra ≤8μm)

- Electro Polished EP Stainless Steel Pipe & Tube (Ra ≤25μm)

- Sanitary Stainless Steel Pipe & Tube

- Capilllary Stainless Steel Pipe & Tube

- Instrument Stainless Steel Pipe & Tube

S32304 is characterized by:

• Good resistance to stress corrosion cracking.

• Good resistance to pitting and crevice corrosion.

• High resistance to general corrosion.

• High mechanical strength.

• High resistance to erosion corrosion and corrosion fatigue.

The specific applications are as follows:

- Storage tanks

- Water heaters

- Heat exchangers

- Pressure vessels

- Feedwater tubes

- Heat exchangers

- Flue-gas cleaning

- Seawater systems

- Desalination plants

- Parts for structural design

- Rotors, impellers and shafts

- Firewalls and blast walls on offshore platforms

- Cargo tanks and pipe systems in chemical tankers

- Piping and instrumentation tubing for general service

Equivalent grades

| DIN | EU EN |

USA – |

Commercial | France AFNOR |

Sweden SS |

Russia GOST |

| 1.4362 | X2CrNiN23-4 | S32304 | 2304 | Z3CN23-04Az | 2327 | 03KH23N6 |

Chemical composition %

| C | Si | Mn | Ni | P | S | Cr | Mo | N | Cu |

| max 0.03 | max 1 | max 2 | 3.5 – 5.5 | max 0.035 | max 0.015 | 22 – 24 | 0.1 – 0.6 | 0.05 – 0.2 | 0.1 – 0.6 |

Mechanical Properties

| Grade | Tensile Strength ksi (MPa) min |

Yield Strength 0.2% offset ksi (MPa) min |

Elongation (% in 50mm) min | Hardness (Brinell) MAX |

Hardness (Rockwell B) MAX |

| Duplex 2304 | 87 (600) |

58 (400) |

25 | 293 | 31^j |

Stainless Steel Tube & Pipe Sizes:

Outsider Diameter OD : 6-630mm ; WT 3-60mm ; L max 16meter

Stainless Steel Tube Delivery Condition:

- Solution Treatment

Stainless Tube Surface:

Acid pickling – pre-passivation process of treating stainless steel parts with an acid solution, typically hydrochloric or sulfuric acid, which can remove oxide scale and heat tint while dissolving steel flecks embedded in the part.

Polishing – P grade sandpaper: P150, P200, P250, P300, P400, P500, P600, P700, P800

Stainless Pipe Inspection and Testing:

Chamical analysis / Tensile test at room temperature / flattening test / ring tensile test / drift expemdomg test / ring expanding test / leak tightness test / Tensile test at elevated temperature / impact test at room temperature / impact test at low temperature / eddy current test / ultrasonic test / magnetic flux leakage test

Stainless Tube Marking and Packages:

In addition to the marking prescribed in specification as client’s request.

Bare / Nylon / Plastic / Wooden Case

Heat Treatment

Solution annealing at 1020 – 1100°C followed by water quenching

CORROSION RESISTANCE:

- Due to its high chromium content of 23%, the corrosion resistance properties of Duplex 2304 are practically equivalent to those of Alloy 316L

- Its duplex microstructure and low nickel and high chromium contents allows Duplex 2304 to have improved stress corrosion resistance properties compared to the 304L and 316L standard austenitic grades.

- More resistant to pitting and crevice corrosion resistance that Alloy 316L

- Outperforms Alloys 304L and 316L in stress corrosion cracking resistance in chloride containing aqueous solutions

- Its corrosion rate in boiling nitric acid (65%) is higher than that of Alloy 316L

- Its high yield strength allows Duplex 2304 to perform well in abrasion/corrosion applications

STRUCTURE

Microstructure of Duplex 2304 is very stable compared to molybdenum containing duplex stainless steels Contains approximately equal amounts of ferritic and austenitic in microstructure after annealing in a temperature

Manufacturing Process

Machining of stainless steel grade Duplex 2304 is performed at low speeds, and constant feeds help to reduce its tendency to work harden. This material is tougher than grade 304 and 316 stainless steels due to its long stringy chip. Chip breakers are recommended. Unlike the 300 series stainless steel, Duplex 2304 steel requires more pressure while performing forming due to its higher yield strength. Its low ductility characteristic tends to make it difficult to perform forming operations.

Welding can be performed using most of the traditional methods such as gas–tungsten arc welding (GTAW), submerged arc welding (SAW), and gas–metal arc welding (GMAW). The filler metal should be a balanced of ferrite/ austenite type like 2205 or 2304.

Hot working can be done after heating the material to 954-1093°C (1750-2000°F), which is followed rapid cooling. Annealing after working is recommended. For annealing, the material is heated to 930-1050°C (1710-1920°F) and then rapidly quenched.

Experienced 15+ Years

Our ability to purchase materials directly from leading mills at the best possible price will give you the competitive edge. This coupled with a skilled workforce dedicated to embracing the demands of the markets.

We Can Supply Follows Products with High Quality:

- Cold Rolled Steel Tube

- Cold Drawn Steel Tube

- Hollow Bar

- Honed Tube

- Plated Tube

- Plated Bar

- Boiler Tube

All Products According Quality Standard Strictly:

- ASTM: ASTM A519, ASTM A513.

- JIS:JIS G3441, JIS G3445, JIS G3466, JIS G3459.

- DIN: DIN1626, DIN1629, DIN2391, DIN2393, DIN2448, DIN2458.

- EN: EN10305.

- BS: BS6323.

Wide Range of Pipes to Fit Your Industry:

- OD from 5mm to 820mm.

- Wall Thickness from 0.1 to 100mm.

- Length up to 50mtr per pc.

Can’t Find What You Looking for? Check Popular Items Blew.

Direct from the Source and Deliver to You in a Very Fast and Efficient Timeframe.